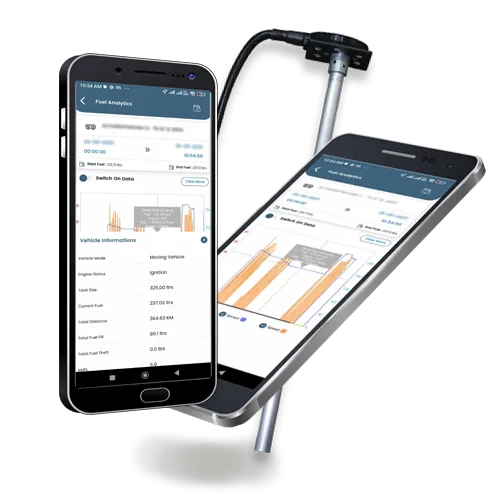

Discover the ultimate fuel monitoring system with VAMOSYS GPSVTS PRO app. Our advanced fuel sensor ensures accurate measurements, efficient fuel management, and enhanced security. Prevent fuel theft, monitor dual fuel tank vehicles, and leverage the power of GPSVTS PRO for comprehensive fuel monitoring.

Experience efficient fuel monitoring with VAMOSYS’ fuel level sensor and the GPSVTS PRO app. Detect fuel theft, prevent drainage, and optimize fuel management with our advanced technology and exceptional accuracy. Harness the power of GPSVTS PRO for comprehensive monitoring and ensure efficient fuel utilization in your fleet.

Get in touch